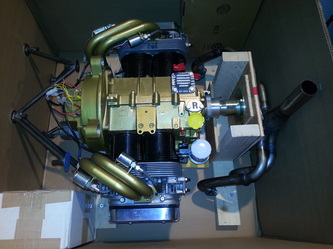

A few basic specs on the engine.

Revmaster R2300.

Rated. 85 hp @ 3200 rpm.

continuous. 80 hp @ 3000 rpm

fuel 91/98 - 100 ll. avgas.

dis. 2331 cc.

carb. revfow 36 mm.

duel alternators 20 amp each.

quad CDI. ignition with 8 coils.

Crank flange SAE #1 4 3/8" bolt PC.

Dry weight 170 lbs - 77.1kg

12/9/2012 this was the day that I picked up the engine from I.T.M. at Tullamarine airport thanks to Victor and Bruce for arranging it for me.

These pictures are were its sitting on the engine room hatch on its way home to devonport after coming all the way from L.A. in America. ITS NEARLY HOME.

It was freighted from L.A. on the 8/sept/2012us.time 9/sept/2012AU.time

15/09/2012 unscrewed the mountings from the shipping pallet these suckers were 5" long

sling up the engine and lift it onto the engine stand, funny how a good plan can go wrong, bloody stand frame wouldn't fit

cause the starter was in the way so installed the engine mount then that wouldn't fit stand frame bolt spacing. to far

apart so had to drill a couple of extensions to fit to the lower mounts. so to mount the engine on the stand this took

from 1000 to 1400, 4hrs.

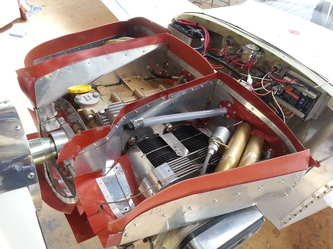

1/8" Fiberfrax was cut and trimmed to fit the 1/4" ply firewall and bonded into place with red high temperature RTV silicone then 1/8" thick by 1 1/4 dia washers were traced were the bolts go through the firewall then the fiberfrax discks removed and washers glued in place to prevent mountings and bolts from crushing the fiberfrax. 0.4mm stainless steel sheet was then cut and trimmed to fit fire wall and bonded on the same way. fuse was then leveled to mark out and get the engine mount level. engine mount was then clamped in place and firewall drilled to suit the engine mount. engine is now temporarily bolted to the firewall using threaded rod until I get the proper mounting bolts and alloy for the backup plates on the inside .

Finally have now got the engine to start have a look for 'revmaster R2300' or 'kr2 first start' or 'my kr2 project' on youtube

update 16/02/2013.

Now started on making the cowl mold, this was done by placing a small sheet of 4mm MDF sheet over the engine, cut the nose section off the cowl I already had (which was going to be to much work to modify) fitted and aligned the nose section behind a 1/4" spacer from the spinner back plate filled with foam and plaster and car filler and then start sanding and shaping untill I got the shape that I liked. pretty straight forward! Now just have to wait untill I get home to take a fiber glass mold off it.

01/Nov/2013. this has been a long slow tedious job constructing the engine baffling, had taken me longer than expected, about 6 days of non stop cutting and shaping the alloy panels, I made my own baffling material as described in Tony Bingelis manual, and it was easier than I expected to make. And as you can see I have also lagged the exhaust to help try to keep the heat away from the electrical's and fuel line.

Time for an update 23-12-2017 the SMURF JET has now had a heart transplant with a jabiru 6 3300 120 hp. As much as the Revmaster was for the power and the speed 'when it was going right' (140Kts) it was always a let down for maintenance and break downs so after the last valve burned out I spat the dummy and went out and bought a jab 6, so here is the video of the first start after the transplant still a little wiring to finish but aother day or so it will all be done then to modify the cowl to suite., that will take a week or two.